Requiring no regular upkeep, these sensors branded as Plug & Forget, allow reliable monitoring data of nuclear infrastructures for decades, without needs for on-site maintenance.

Opsens unique fiber optic technology can easily sustain dose in megaGray (MGy) and is specifically adapted for high radiated environment:

- Relies on pure silica multimode fiber, with ultra low OH– and Cl–

- Using broad spectrum of light to afford possible absorption lines that occur at specific wavelengths

- Manufactured with passive and radiation resistant material

Nuclear waste management

Using hydrostatic pressure measurement, the unique differential pressure sensor enables reliable and real-time surveillance of water level in Spent Fuel Pool.

Plug & Forget Extensometer and load cells with almost no sensitivity to temperature variations are deployed in concrete assets for structural integrity surveillance where radiations generate a significant amount of heat.

Turbine instrumentation

Low profile pressure sensors are welded directly on the blades to estimate rotation speed, without generating disturbances such as cavitation. Marinized strain gages provide permanent deformation surveillance of critical alloy components.

Tightening surveillance of fasteners

Developed in partnership with Cathelain, the C-Bolt® is a revolutionary system for remote real-time detection of bolt loosening and accurate bolt tightening.

The benefits of the instrumented bolt are significant:

- Time saving

- Safety of human workers

- Cost saving (Predictive maintenance)

- Easy installation (no specific tool required)

The product won many awards since its releases such as the WNE awards 2021 in the nuclear Safety Innovation Category and Best New Technology at the Global Industry Exhibit 2019. See demonstration video here.

Valve control

For Safe and Reliable Flow measurement in radiated environment, valves could be equipped with a combination of pressure and temperature sensors. Even the stem position could be tracked with an optical LVDT.

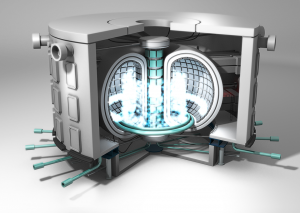

iter ready

Since 2017, the technology has been tested and validated for the ITER project by various independent labs around the world. The technology is now required for most critical components surrounding the reactor such as cooling systems, cryopumps, and Cold Valve Boxes. Tested in very intense magnetic fields of several tens of Tesla, the sensors did not show any kind of susceptibility to these interferences.

Since 2017, the technology has been tested and validated for the ITER project by various independent labs around the world. The technology is now required for most critical components surrounding the reactor such as cooling systems, cryopumps, and Cold Valve Boxes. Tested in very intense magnetic fields of several tens of Tesla, the sensors did not show any kind of susceptibility to these interferences.

You need a specific Fiber Optic sensor?